What services we provide

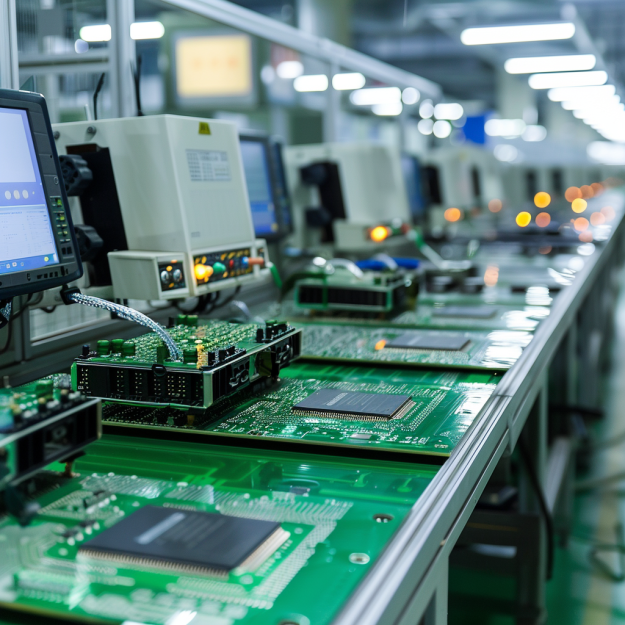

One-stop PCBA solution

From fabrication to assembly, a turnkey solution designed to fulfill all your requirements.

Efficient Production Line Setup

Our fully equipped production line features programming capabilities to meet production testing needs. With SMT MP and multi-functional assembly lines, as well as DIP plug-in & welding facilities, we ensure standardized operations and efficient assembly.

Advanced Process Capabilities

Our process capabilities cover advanced SMT and DIP assembly methods. SMT features reflow soldering for tiny components, BGA with pad pitches up to 0.3mm, and IC pin pitches up to 0.3mm. DIP options include through-hole and selective wave soldering, with hand soldering available.

SMT Capacity

SMT equipment enables precise placement and soldering for small components, with BGA pad pitches as precise as 0.30mm. Our process includes 3D solder paste testing and MES implementation for quality enhancement.

Quick Response

In response to growing demand for samples and small-lot assembly, we're expanding our production lines to nine. Our aim? To ensure quick responses, with delivery in 24 hours or even 8 hours if necessary.

How we work 需要确认流程

Get instant quote

Begin by receiving an immediate online quote by providing details such as the quantity required for PCB assembly. Even if certain specifics like the number of Unique Parts, SMT pads, or through holes are uncertain, you can still proceed.

Upload Gerber file

Next, upload your Gerber files, Parts List (BOM), and Centroid files. This step ensures a faster and more accurate quoting process.

Manufacturing

Once the manufacturing process begins, we'll keep you informed by sending sample pictures for your confirmation. This ensures transparency and allows you to verify the progress of your order.

Testing

Testing and quality assurance will be carried our thoughout the manufactuing process. If there are any specific testing or programming requirements for your project, please include them in your quote. This enables us to tailor our quality assurance procedures accordingly.

Delivery

Finally, upon completion, your products will be promptly shipped to your designated location. Our efficient delivery service ensures that your order reaches you in a timely manner.